Production Optimized

Automation & Engineering Integrator for Process Manufacturers

Transform your productivity with automation solutions. Whether you are bringing a new product to market or working to increase plant efficiency and scale, EPIC enables you to bring your ideas to reality.

Automation Solutions

Filling & Packaging

Inspection Systems

Damages and Defects

- Packaging and Label Defects

- Product Defects

- Bent Dip Tubes

- Damaged or Absent Caps and Closures

Characters and Codes

- Dot Matrix and Non-Dot Print

- OCR and OCV

- Lot, Date, and Bar Codes

- 1D and 2D Bar Codes (QR Codes and Custom Artwork)

Seal Integrity

- Holes and Cuts

- Channel Leakers

Alignment and Positioning

- Graphic Position and Alignment

- Misaligned and Mislayered Webbing

- Missing or Misapplied Labels and Lids

- Part Position Feedback Systems

Match and Verification

- Lid and Label Artwork Match

- Artwork and Recipe Verification

Filling and Orientation

- Bottle Presence and Orientation Before Filling

- Spray Trigger and Cap Orientation

- Overfilling and Leaking

- Foaming Detection

Other Inspections

- 360-Degree Bottle Inspection

- Perforation Presence and Depth

- Graphical Inspections

- 3D Inspections

Track and Trace

Integrated Controls and

Rejection Solutions

Robotic Kitting

Process Systems

- Late Product Differentiation

- Product Recovery (Pigging)

Palletizing & Material Handling

Robotics

Vision Guided Robotics (VGR)

- Quality Inspection

- Random Part Presentation

- Vision Guidance

Packing and Palletizing

- Case Packing and Unpacking

- Palletizing and De-palletizing

- Collaborative (Cobot) and Industrial Robot Applications

Robotic Kitting

- Putwall

- Goods-to-Person Picking

- Induction

Material Handling

- Machine and Press Tending

- Pick and Place

3D Bin Picking

- Part Sortation

- Machine or Conveyor Loading Packaging

- Assembly

Precision Assembly

- Component Assembly

- Part Insertion

- Nut Runners and Screw Driving

Other Applications

- Adhesive Dispensing

- Lab Analysis

- Mobile Robotics

- Wash-Down and Clean-Room Robotics

Conveyor Controls

Pallet Inspection Systems

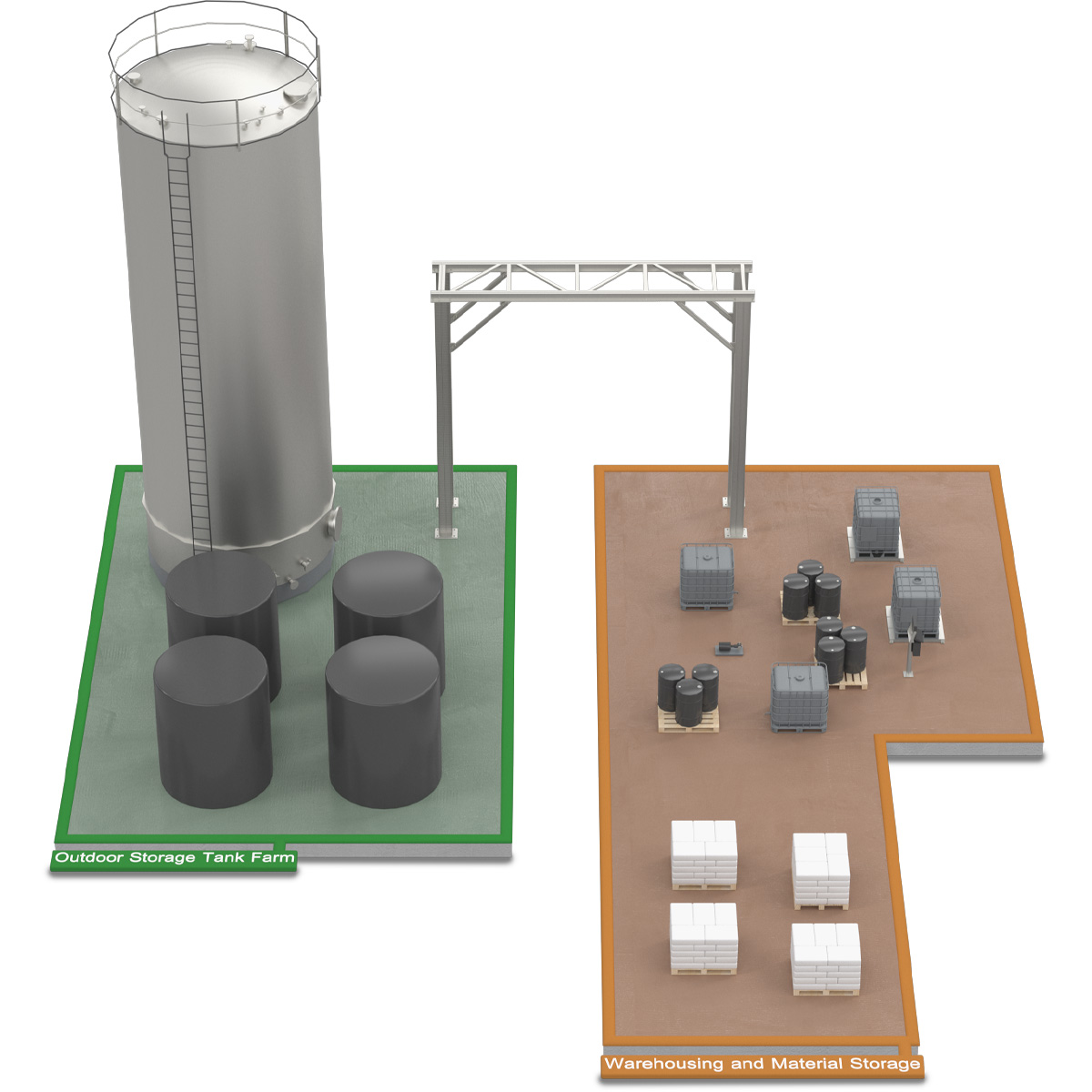

Outdoor Storage Tank Farm

- Bulk Chemical and Material Storage

- Truck and Rail Loading and Unloading

- Foundations and Containment

- Temperature Control Skids (TCUs)

- Pipe Racks

- Material Transfer Skids

Warehousing & Material Storage

- Engineering and Design Services

- Bar Code Scanning

- Racks

- Rack Density

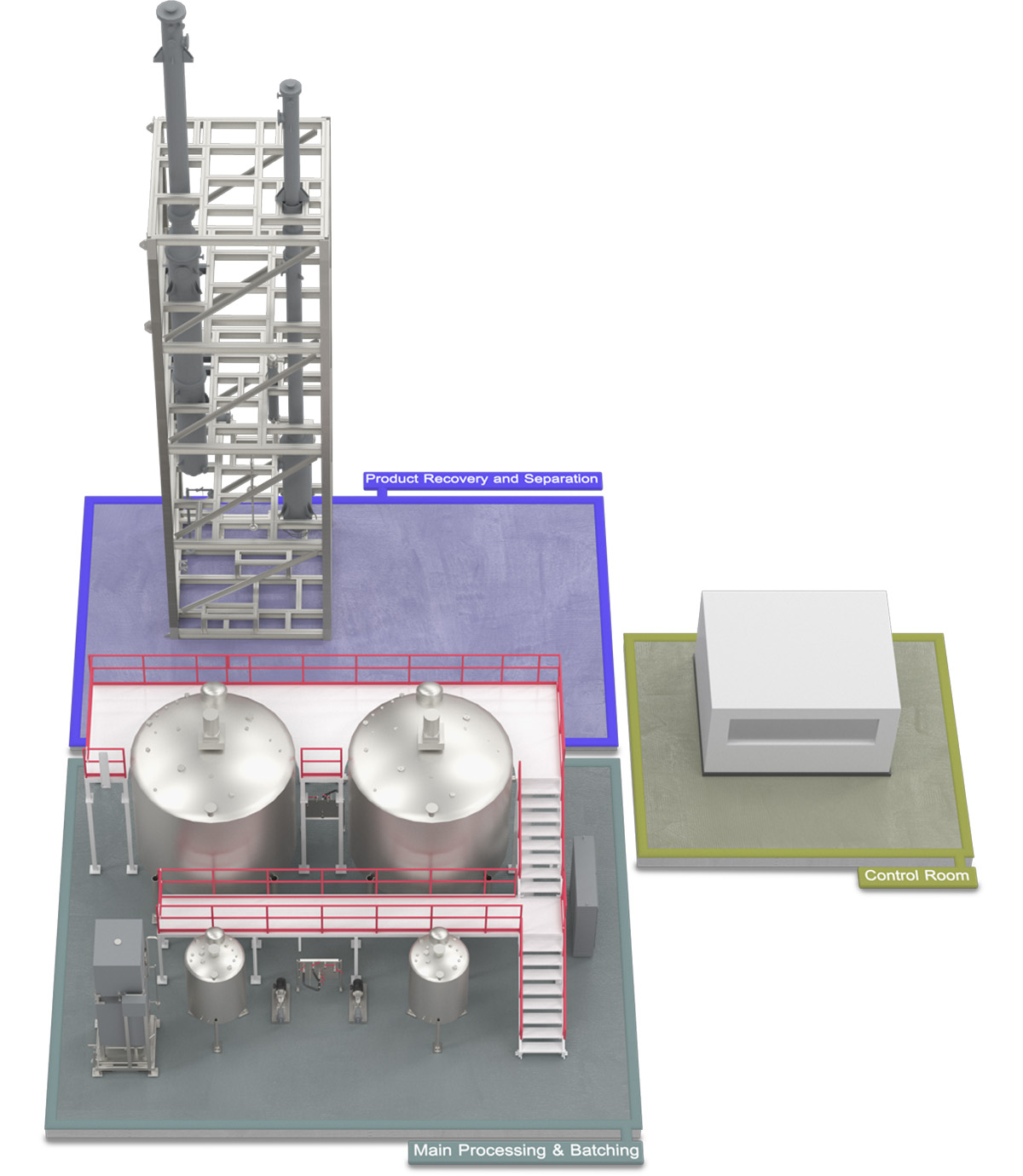

Separation & Absorption

Separation

- Distillation Tower

- Batch Still Systems

- Purification Systems

- Fat, Oil, and Grease Capture

Absorption

- Carbon Capture and Emissions Control

- Scrubbing

Recovery Systems

Plant Automation

System Controls

- Control Platform Upgrades

- Control or HMI Upgrades

- Motor Controls and VFDs

- Instrument Wiring

- Calibration and Verification

Skid-Based Automation

- Ground-up Design Build

- Automation For Process Skids

Panel Fabrication

- NEMA Rated

- Explosion Proof

Safety Instrumentation Systems (SIS)

Obsolescence Upgrades

Formulation Changes and Recipe Management

- Instrumentation Upgrades

- Programming

- Minor Reconfiguration

- Batch Sequence Changes

Remote Monitoring Systems

- System Design Build

- Local Networking and Connectivity

Automation Services

- System and Line Integrations

- Plant Evaluations and System Audits

- Engineering and Design Services

- PLC and HMI Programming

- Remote Troubleshooting

- Plant Floor Power Distribution

IT Integration Services

- Digital Twinning

- Data Management and Collection

SCADA Systems

Main Processing & Batching

Applications

Inline Blending Systems

Batch Blending Systems

- Mixing

- Compounding

Reacting Systems

- Encapsulation

- Emulsification

- Polymerization

- Esterification

- Extraction

Minor Ingredient Handling Systems

- Super Sack Systems

- Powder Conveyance

- Liquid Tote-to-Tote

Washing and Drying Systems

For

- Industrial Chemicals

- Specialty Chemicals

- Agricultural Chemicals

- Food and Beverages

- Household Cleaners

- Soaps and Detergents

- EV Batteries

- Fragrances

- Resins and Adhesives

Robotics

- Machine Tending

- Welding and Tool Hardening

Outdoor Storage Tank Farm

- Bulk Chemical and Material Storage

- Truck and Rail Loading and Unloading

- Foundations and Containment

- Temperature Control Skids (TCUs)

- Pipe Racks

- Material Transfer Skids

Warehousing & Material Storage

- Engineering and Design Services

- Bar Code Scanning

- Racks

- Rack Density

Separation & Absorption

Separation

- Distillation Tower

- Batch Still Systems

- Purification Systems

- Fat, Oil, and Grease Capture

Absorption

- Carbon Capture and Emissions Control

- Scrubbing

Recovery Systems

Main Processing & Batching

Applications

- Inline Blending Systems

- Batch Blending Systems

- Reacting Systems

- Minor Ingredient Handling Systems

- Washing and Drying Systems

For

- Industrial Chemicals

- Specialty Chemicals

- Agricultural Chemicals

- Food and Beverages

- Household Cleaners

- Soaps and Detergents

- EV Batteries

- Fragrances

- Resins and Adhesives

Plant Automation

System Controls

- Obsolescence Upgrades

- Skid-Based Automation

- IT Integration Services

- System Audits

Automation Design Services

Safety Instrumentation Systems (SIS)

Formulation Changes & Recipe Management

Remote Monitoring Systems

SCADA Systems

Palletizing & Material Handling

Robotics

- Robotic Palletizing

- Cobots (Collaborative Robots)

- Industrial Robots

- Mobile Robotics

- Vision Guided Robotics (VGR)

- Packing

- Palletizing

- Precision Assembly

- Materials Handling

- 3D Bin Picking

- Machine Tending

- Welding and Tool Hardening

Conveyor Controls

Pallet Inspection Systems

Filling & Packaging

Inspection Systems For

- Damages and Defects

- Characters and Codes

- Seal Integrity

- Alignment and Positioning

- Match and Verification

- Filling and Orientation

- Other Inspections

Track & Trace

Integrated Controls & Rejection Solutions

Robotic Kitting

Process Systems

- Late Product Differentiation

- Product Recovery (Pigging)

Our Solutions

EPIC Systems is a multidisciplinary engineering integrator specialized in industrial automation for process manufacturers. We deliver solutions in the following areas:

Process Systems

Machine Vision

Robotics

Industrial Automation

Solve Production Challenges

Industrial automation is solving some of the most complex manufacturing challenges our customers face. From rising costs to labor shortages, supply chain disruptions, and sustainability EPIC Systems is your partner.

Rising Costs

Labor Shortages

Supply Chain Disruptions

Sustainability

Achieve Success

Optimize every area of your operation with one team.

Our capabilities in project methodology, design-build, fabrication, and automation programming will help you achieve your goals.